Yamaha YRP10 Solder Paste Press Machine

High Performance Solder Paste Printing Machine

High-speed, high-quality solder paste printing machine that completes automatic setups and changeovers. It also supports both single-lane and dual-lane production.

- High-speed printing performance Core cycle time: 6 seconds

- Printing accuracy μ±6σ : ±16μm Cpk≧2.0

(measured using CeTaQ under YAMAHA’s optimum conditions) - Fully automatic installations and modifications

- Fully independent production with dual lanes

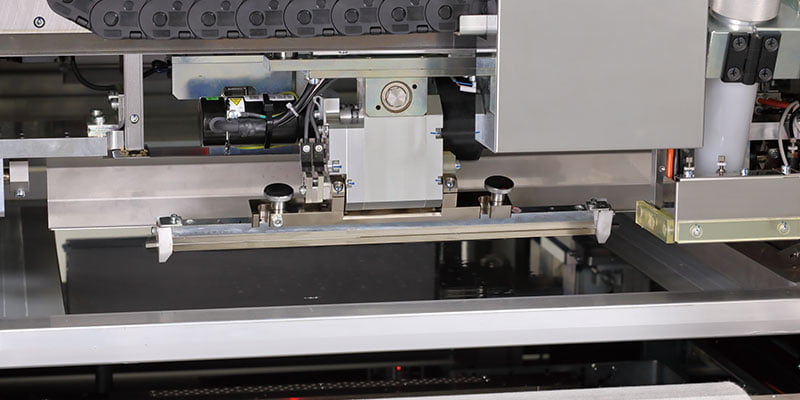

Single-head, easy to use, high quality, extremely durable single-head

Significantly reduces working hours thanks to fully automatic installations and changes

Automatic installation function and double lane production

W330mm large PCB dual lane transfer

For customers who want to perform long-term, unmanned, uninterrupted solder printing

- The template is automatically changed by pre-setting the template for the next model and booking production.

- The push pin arrangement is automatically changed in parallel with the change of the template, reducing operator workload and the number of errors in pin arrangement.

- It transfers the solder to a new mold while preserving its rolling shape and eliminates waste in the rolling process.

- Solder is supplied automatically for hours with a 12 oz solder syringe PSC.

- The solder width is always monitored and kept constant, ensuring stable printing quality.

- The syringe can be replaced in one minute, minimizing downtime.

For customers who are looking for difficult and high quality printing

- μ±6σ : ±16μm Cpk≧2.0 rigid body that realizes printing precision

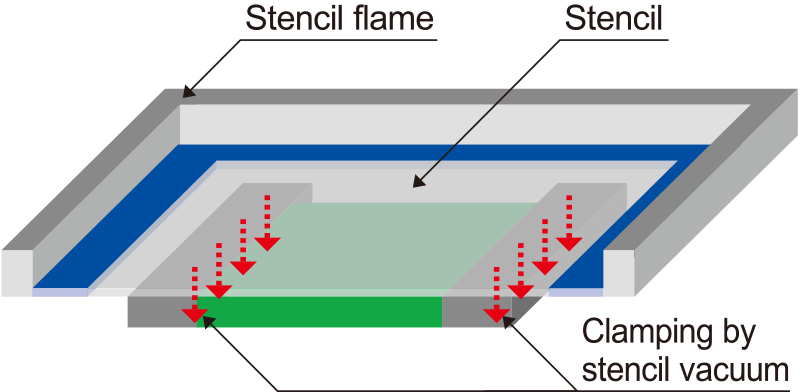

- Contact with PCBs is ensured by a stencil vacuum system that improves solder filling.

- The printing position is automatically adjusted by SPI connection, realizing high-precision printing.

- YAMAHA’s original 3S head with changeable wiper attack angle.

- Automatic Push-up Pin Change system can be supported by the entire board.

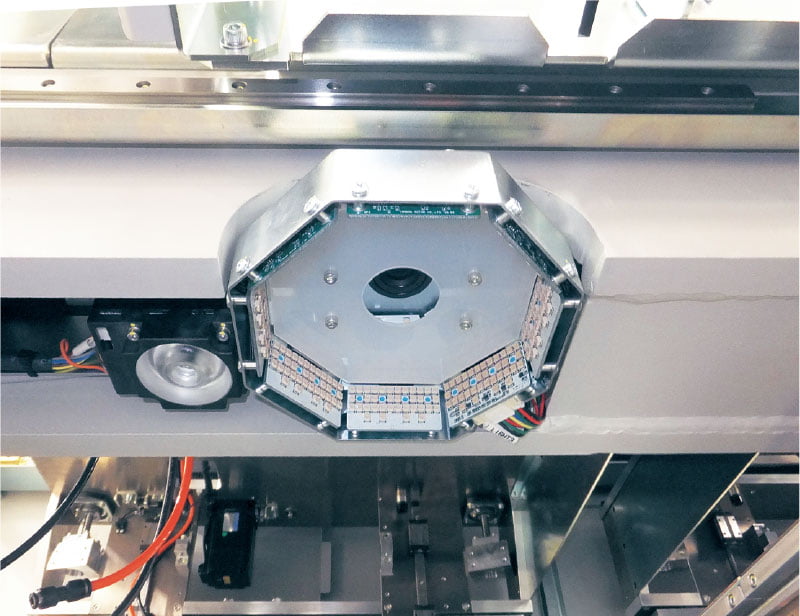

- High-speed, high-precision onboard SPI using dedicated cameras.

- Performs duplex printing and clearing from the inspection results of the built-in SPI.

For customers who are looking for difficult and high quality printing

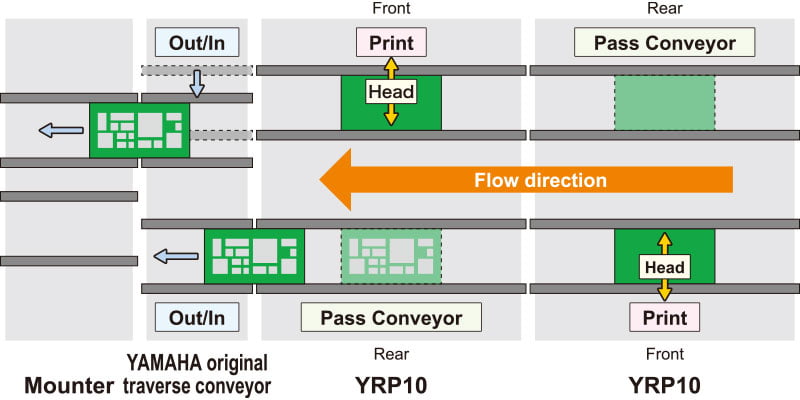

Single/dual ribbon printer adopting a common platform

- The two-printer flat layout allows various automatic setup functions to be adapted to the dual ribbon.

- YAMAHA’s original cross conveyor provides flexible connection to downstream equipment.

- Supports dual lanes for large PCBs up to 330mm wide.

- By commonizing parts, the number of required maintenance parts is minimized.

It offers both high quality and super precise printing!

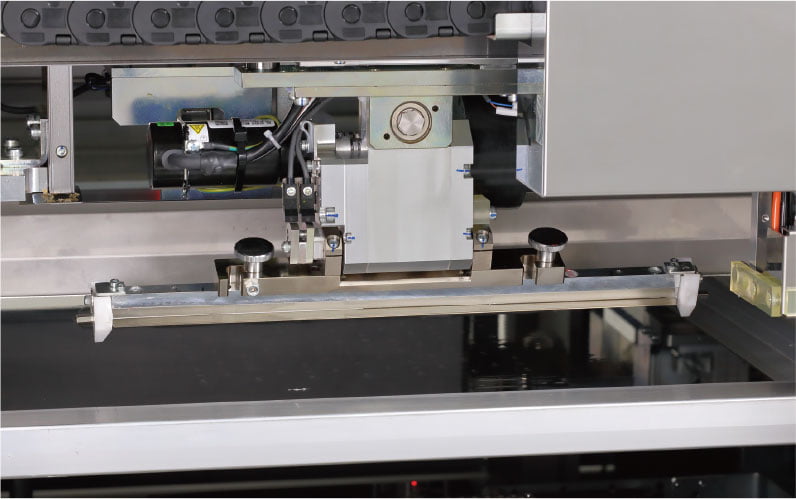

YAMAHA original 3S head

Program the squeegee’s attack angle and speed to an ideal setting to ensure optimal printing conditions that match the solder used.

Template vacuum

The stencil vacuum mechanism ensures consistent, high-accuracy printing without being affected by stencil drop. It also significantly reduces set-up time as no offset input is required during the back-and-forth printing motion.

Printer's built-in inspection camera

The stencil vacuum mechanism ensures consistent, high-accuracy printing without being affected by stencil drop. It also significantly reduces set-up time as no offset input is required during the back-and-forth printing motion.

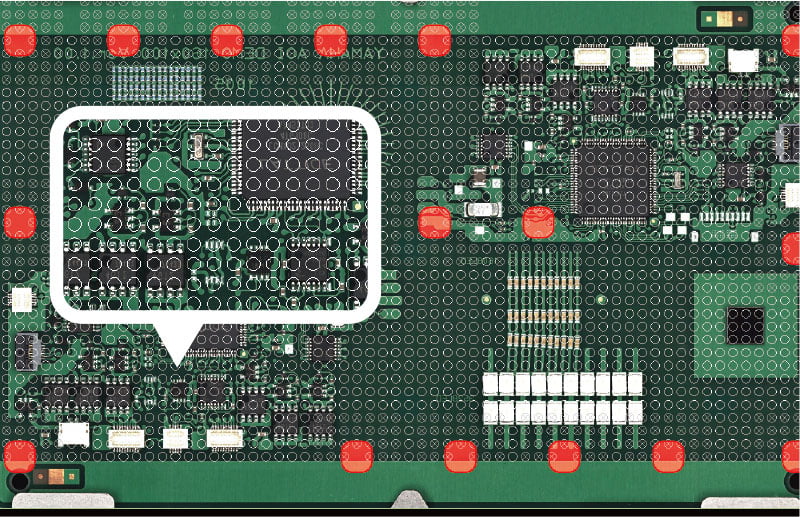

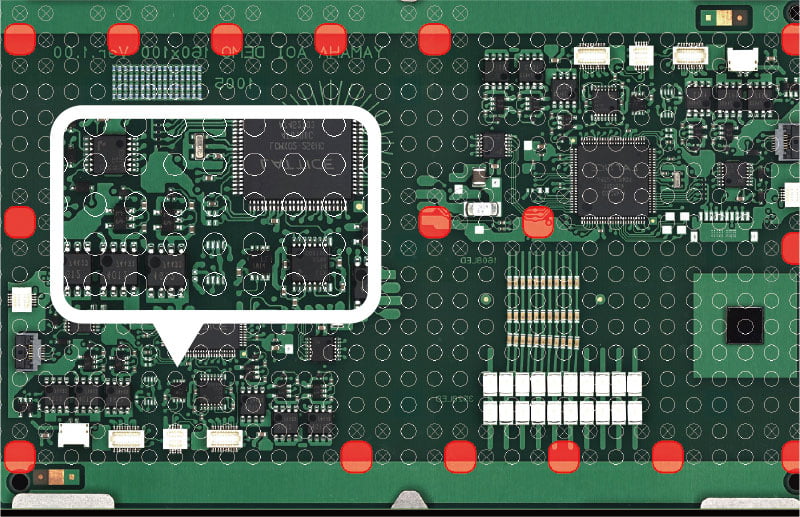

Push-up pins for high-density PCBs

Up to 200 pins can be arranged. In addition to the 5 mm pitch matrix plate, a 2.5 mm pitch matrix plate with greater arrangement freedom is also available as an option.

2.5mm pitch specification

5mm spacing specification

FEATURES

| YRP10 | |

|---|---|

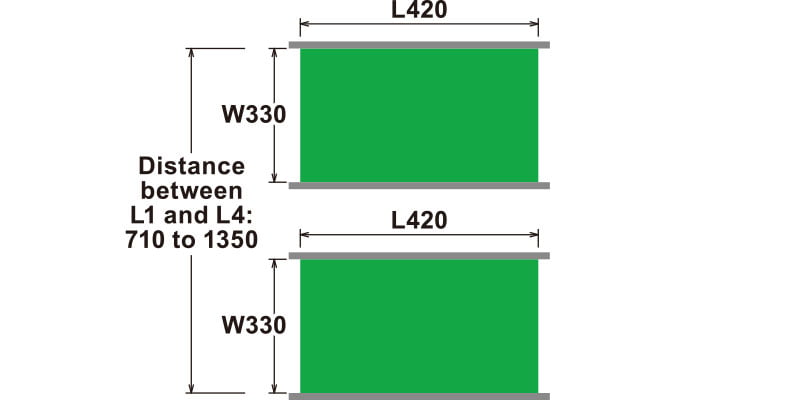

| Applicable PCB | Single lane: L510 x W510 mm to L50 x W50 mm<br>Double lane: L420 x W330 mm to L50 x W50 mm |

| Print heads | 3S head (3S: Swing Single Squeegee) |

| Printing accuracy | Positioning repeatability (±6σ): ±8 μm Cp≧2.0<br>Printing accuracy (μ±6σ): ±16 μm Cpk≧2.0 * |

| Core cycle time<br>(Printing not included) | 6 seconds |

| Applicable stencil size | L750 x W750mm, L736 x W736mm (29″), L750 x W650mm, L650 x W550mm<br>L600 x W550mm, L550 x W650mm, L584 x W584mm (23″) |

| Power supply | Single phase AC 200 to 230V +/-20V |

| Air supply source | 0.4MPa or more |

| External dimensions<br>(excluding projections) | L1,640 x W1,840 x H1,525 mm (Single lane standard specification)<br>L3,560 x W2,300 x H1,525 mm (Double lane specification) |

| Weight | Printer: Approx. 1,710kg<br>Cross conveyor: Approx. 450kg |

MACHINE DIMENSIONS

(Single Lane)

(Double lane)