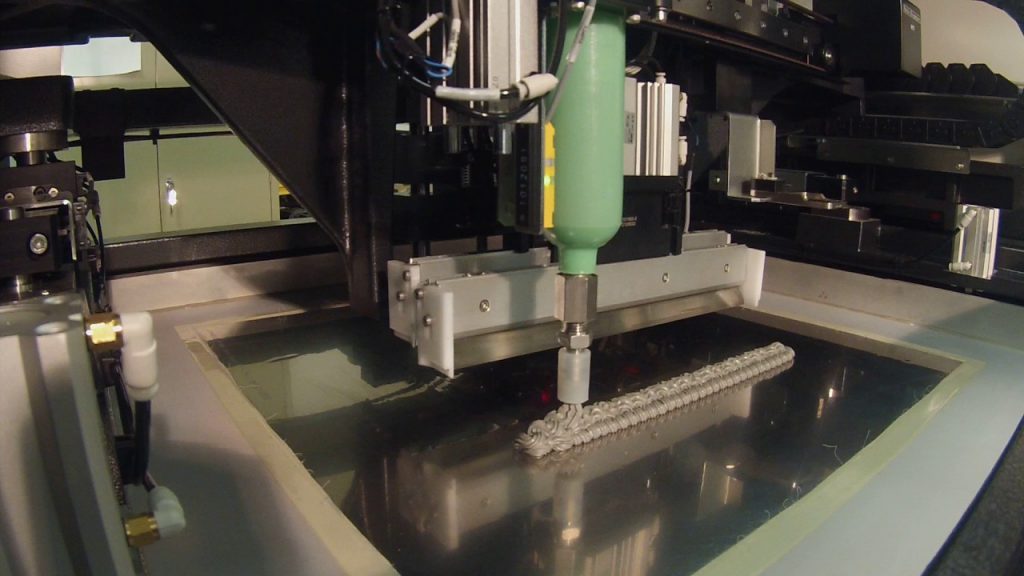

Screen Printer Machine

Your dream cream solder printer machines

Up to 200,000 components per hour placement speeds. Machines still in operation in Turkey since 1995. Beyond SMD placement machine, 3D MID and amorphous component placement. Groundbreaking Japanese precision with MACS verification technology. Only at Yamaha.

MPM Momentum II

12.5µm @ 6σ, Cpk ≥ 2 printing precision. 6 to 10 seconds cycle time. Advanced optical control (SPI) and statistical analysis (SPC) capabilities.

MPM Edison

The favorite of automotive and smart device manufacturing is the press with +/- 8 micron alignment and +/- 15 micron (≥2 Cpk @ 6σ) wet print repeatability.

Stop cleaning the sieve and let the machine do it itself

Sieve cleaning is critical to preventing process errors. Do not leave sieve cleaning to operators. Let the machine perform the sieve cleaning itself at programmed intervals in the most proper way. Do not stop production to clean the sieve. Eliminate unnecessary labor. Prevent errors in card printing due to sieves that are not cleaned properly and on time.

Let the screen printer machine add the ideal thickness of solder paste.

Let it measure as it decreases, and complete exactly as much as it is missing. Thus, eliminate process errors caused by adding more or less solder than necessary. The operator should not stop the machine and waste labor to add solder.