Specially Designed Precise Atmosphere and Temperature Controlled Ovens

Excellence in Industry and Laboratory. High Precision Atmosphere and Temperature Controlled Furnaces

Understanding Controlled Atmosphere Furnaces

Applications of Specially Designed Ovens

Specially designed furnaces find application in various fields. In industrial processes, they are used for heat treatments, metalworking, and materials testing. Laboratories use these furnaces for experiments that require controlled atmospheres and precise temperatures. Manufacturing industries rely on these furnaces for processes such as component testing and product development. The versatility of these furnaces makes them indispensable in different sectors.

Industrial Processes

In industrial settings, these furnaces are used for processes that require tight control over atmospheric conditions and temperatures. This includes annealing, which softens metals and increases their ductility, and sintering, where powdered materials are fused into solid parts.

Laboratory Use

Laboratories use these furnaces for experiments that require controlled environments. Materials science, chemistry, and physics research and development often rely on this equipment to ensure repeatability and accuracy of experimental results.

Manufacturing

Manufacturing industries use controlled atmosphere furnaces for processes such as heat treatments that improve the properties of metals and alloys, and component testing, which ensures that parts meet stringent quality standards.

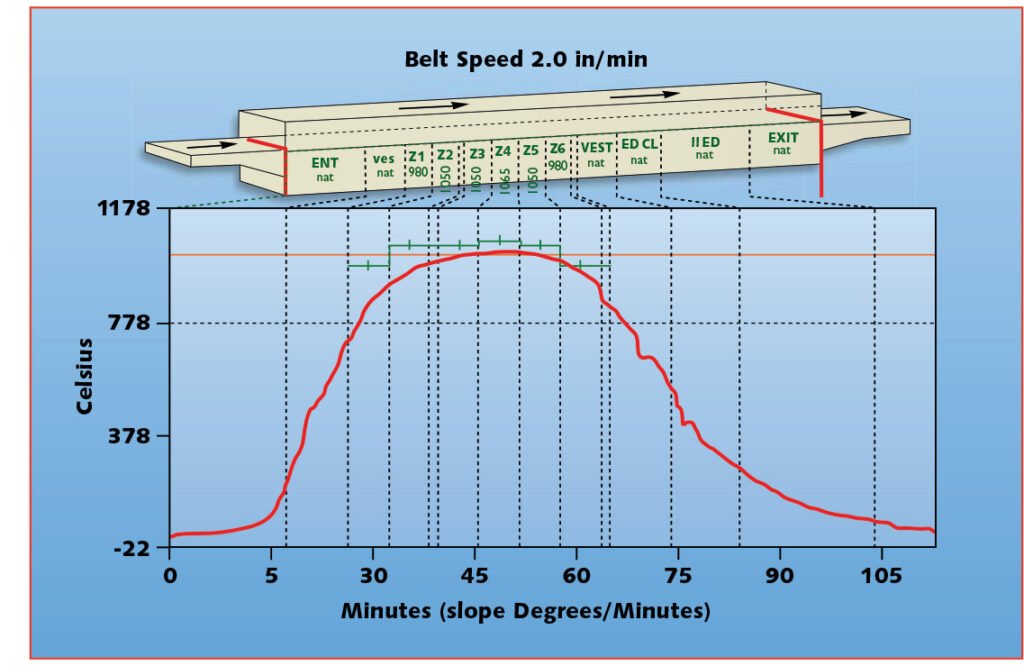

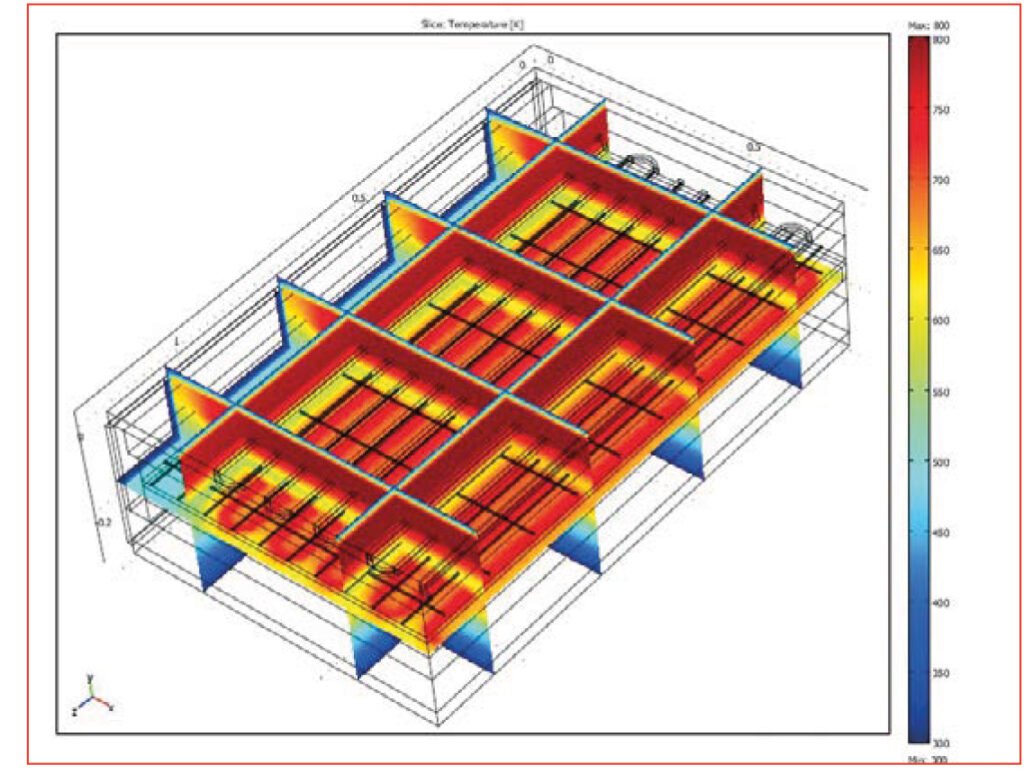

The Importance of Precision in Temperature Control

Temperature control is a key feature of these specialty furnaces. Precise temperature regulation ensures that the materials being processed are processed evenly, which is vital to maintaining the integrity and properties of the materials. In processes such as annealing, sintering and brazing, even small changes in temperature can significantly affect the quality of the final product. Therefore, the ability to maintain exact temperature settings is a key advantage of specially designed precision atmosphere and temperature controlled furnaces.

High Sensitivity

These furnaces are designed to offer high precision in atmosphere and temperature control. This precision is critical for processes that require precise conditions to achieve desired results.

Reliability

Reliability is another important feature of these furnaces. They are built to operate consistently over long periods of time, minimizing downtime and ensuring industrial processes continue uninterrupted.

Security

Safety features are an integral part of the design of these furnaces. These include advanced monitoring systems that detect deviations from set parameters and take corrective action to prevent accidents and ensure the safety of operators and equipment.

Special Design Key Features of Ovens

Technological Innovations in Special Ovens

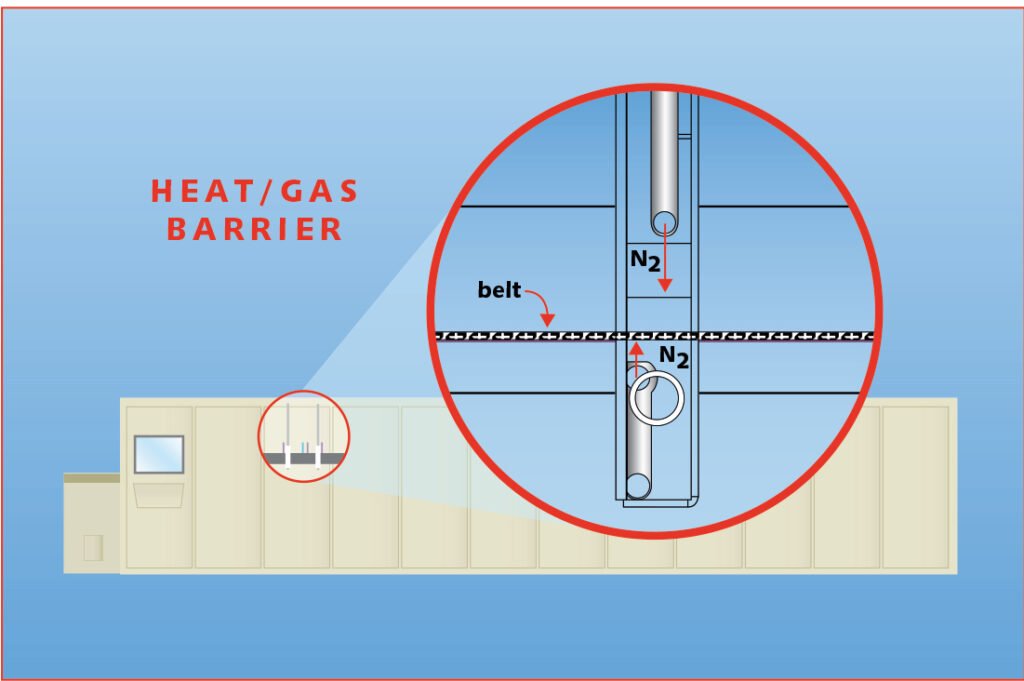

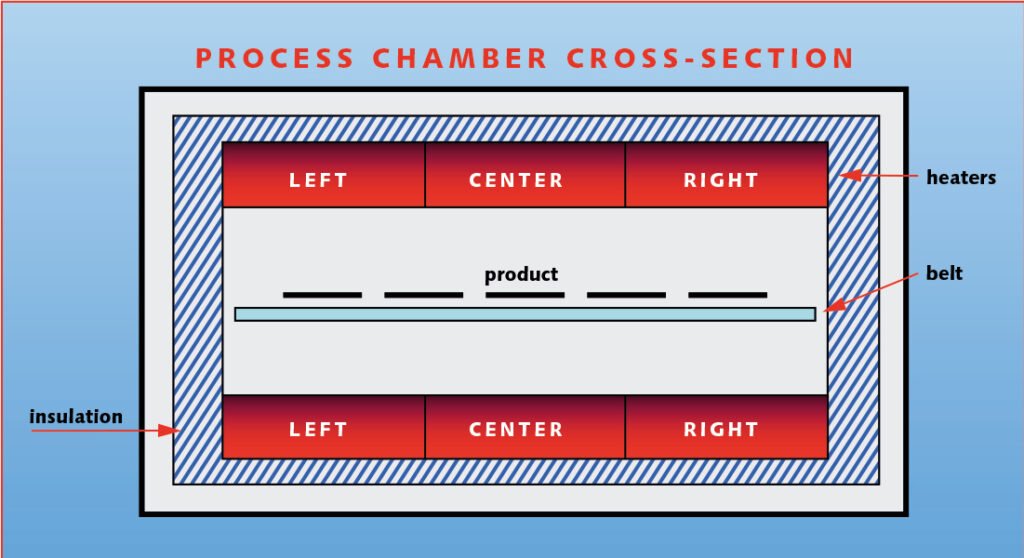

Atmosphere Control

The Controlled Atmosphere Furnace from BTU features precise atmosphere controls to monitor critical parameters in the process chamber. The gas control panel is designed to operate safely/securely while minimizing operator intervention.

Advanced Control Systems

Modern ovens are equipped with advanced control systems that allow precise regulation of temperature and atmosphere. These systems use sophisticated algorithms and sensors to monitor and adjust conditions inside the oven in real time.

Products

Benefits of Specially Designed Ovens

The benefits of using custom ovens include increased performance, energy efficiency, and customization options.

Increased Performance

These ovens offer superior performance in temperature and atmosphere control. This ensures that processes are run under optimal conditions and high-quality output is achieved.

Energy Efficiency

Energy efficiency is another important benefit. Custom ovens are built to minimize energy consumption, which reduces operating costs and has a positive impact on the environment.

Customization Options

Customization options allow these ovens to be designed to meet specific requirements. This flexibility ensures that the oven is designed to meet the unique needs of different processes and applications.

Things to Consider in

Special Design Ovens

Choosing the Right Oven for Your Needs

Choosing the right oven involves evaluating your needs and consulting with experts.

Assessment of Requirements

The first step in choosing a furnace is to evaluate the specific requirements of your process. This includes determining the required temperature range, atmosphere, and other critical parameters.

Installation and Maintenance

To ensure optimal performance and longevity of custom designed furnaces, proper installation and regular maintenance are essential.

Consult with Experts

Consulting with experts provides valuable information and guidance in selecting the appropriate furnace. ProSMT helps you understand the specifications and capabilities of different furnaces and provides the best option for your needs.

Proper Installation

Proper installation is critical to the safe and efficient operation of your furnace. This includes installing the furnace according to manufacturer specifications and ensuring all connections and systems are properly positioned.

Regular Maintenance

Regular maintenance helps keep your furnace in good working order. This includes routine checks, cleaning and maintenance of components, and helps prevent breakdowns and extend the life of your furnace.