SMD X-RAY Counting Machine

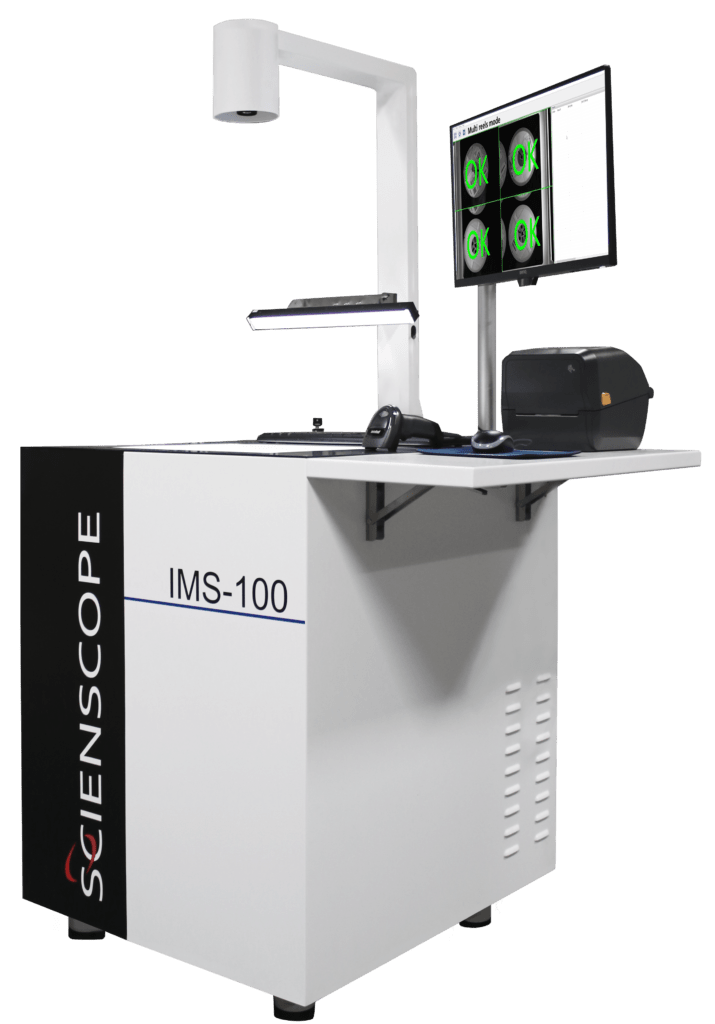

IMS 100 X-Ray Component Counting Machine

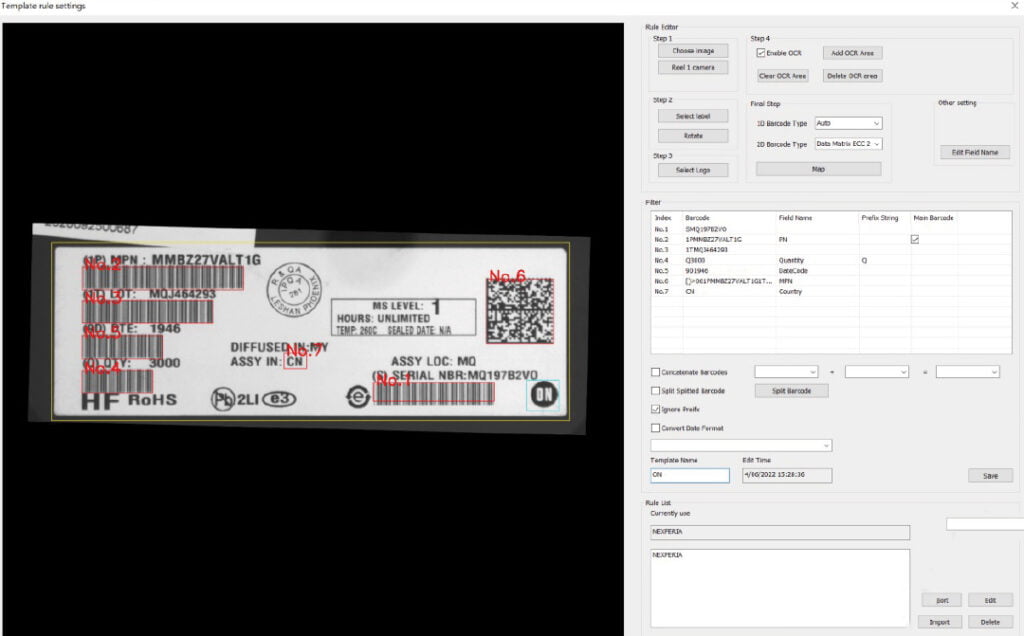

The high-resolution camera system can read any type of barcode and even characters with image-based algorithm. This will help you automate your incoming material process and make the relabeling process easy, fast and free from operator error.

Read all types of barcodes with the high-resolution camera system .

High-resolution camera system with image-based algorithm reads any barcode, even with defects.

Easily track your materials with the unique ID feature.

Read all types of barcodes with the high-resolution camera system, automate incoming material processing and eliminate errors.

Scienscope IMS-100 is a high-resolution camera system that can read all types of barcodes. It helps automate the incoming material process, eliminate errors and easily track your materials with its unique ID feature. With Scienscope IMS-100, you can increase the efficiency and accuracy of your production lines and save time and money.

Increase the efficiency and accuracy of your production lines.

Scienscope IMS-100

- High resolution camera system that can read all types of barcodes

- Automatic incoming material process

- Eliminates errors

- Unique ID feature

- Increases efficiency and accuracy

- Saves time and money

En iyi kamera

Alt Kamera

4 küçük 7 inç makaraya kadar

Increase the efficiency and accuracy of your production lines.

Easily track your materials with the unique ID feature.

Using such a system will streamline your incoming material process and eliminate human error errors from data entry to relabeling. The equipment has a top scanner option that offers the same state-of-the-art features but eliminates manual rotation of the material when there are double-sided labels.IMS-100 offers a unique ID feature that allows easy tracking and identification of all materials used in the production process in real time, from the moment they enter the warehouse to the finished product. Unique ID is a must in the days when everything is moving towards Industry 4.0. This feature provides invaluable insight into your production process, allowing you to monitor and optimize your operations for maximum efficiency and output while eliminating human error.

Hardware

| Operating System | Central Computer |

| Spool Size | 7″, 10″, 13″ and 15″ |

| Compatible Spool Size | Up to 4 small 7” reels at a time or 1 reel/pack of different sizes |

| Types of Examination | Standard SMT and TH, Standard reels up to 15″ in diameter, Cut Strips, ESD Bags, JEDEC |

| Label Printing | Software interface for automatic label printing of labels with customized features |

| Printer Type | Zebra (optional) |

| Optical Camera | 20 Megapixels |

| Best Browser | 20 Megapixel Camera (optional) |

| Smart Mobile Application | Optional |

Software

| Reads Barcode Information and Loads MES / ERP System | Yes |

| Validates Labels and Prints Labels Automatically | Yes |

| Identify Various Types of Barcode Formats | Yes |

| OCR Capacity | Yes |

| Date Code Translation | Yes |

| Industry 4.0 | Yes |

| Customize Process Flow | Yes |

| Mobile Application for Non-Spool Packages | Yes |

| Windows 11 Ready |

General Features

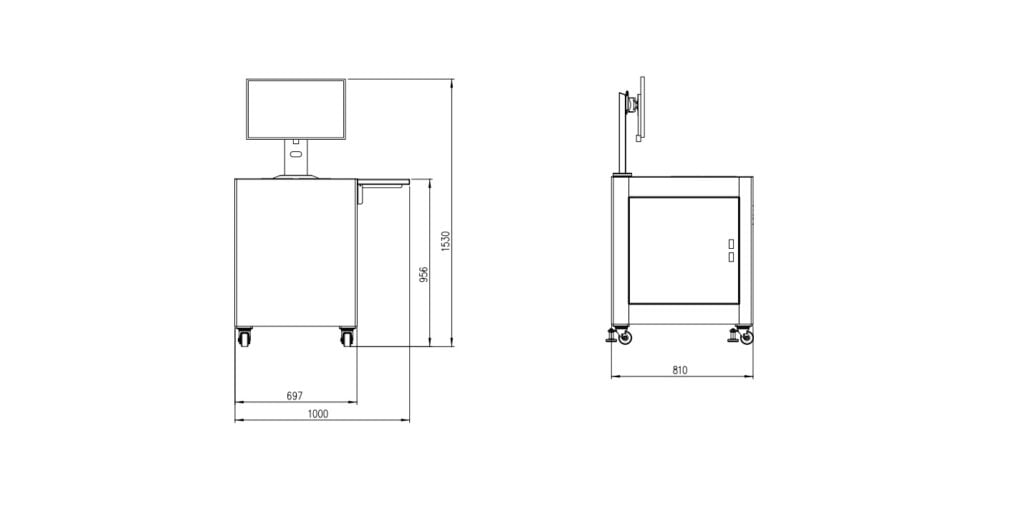

| Dimension | (L/W/H): 1000mm x 810mm x 1530mm / 39.4” x 31.9” x 60.2” |

| Weight | 194.6 kg / 429 lbs |

| Electric | AC110-240V 50 / 60Hz |