PCB Surface Cleaning Machine

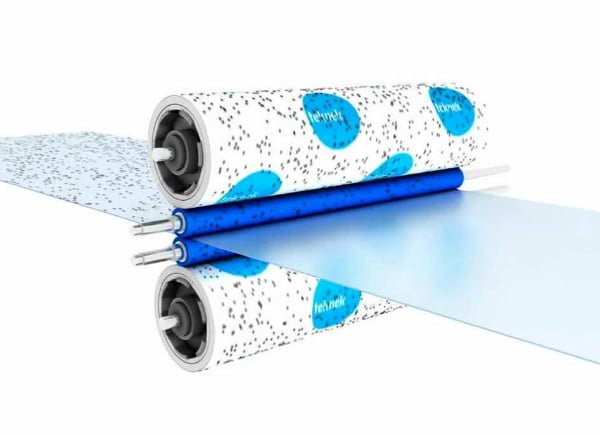

Teknek SMT-II PCB

Cleaning Conveyor

Teknek SMT-II PCB yüzeyi temizleme makinesi, yada PCB yüzey temizleme konveyörü, krem lehim baskısından hemen önce PCB yüzeylerini temizler. Elektronik kart dizgisi ile tam entegre inline çalışır. Bu makine ile proses hatalarını %70’e varan oranlarda iyileştirebilirsiniz.

Prevent dust and dirt from accumulating as a result of electrostatic charging.

Before the cream solder printing machine (screen printer)

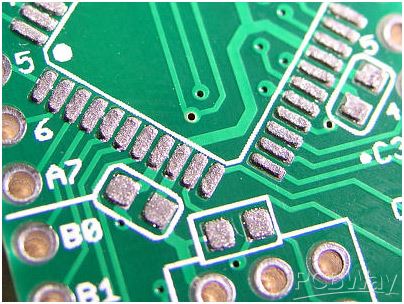

It is used to clean the dust and contaminant particles accumulated on PCBs just before the cream solder printing.

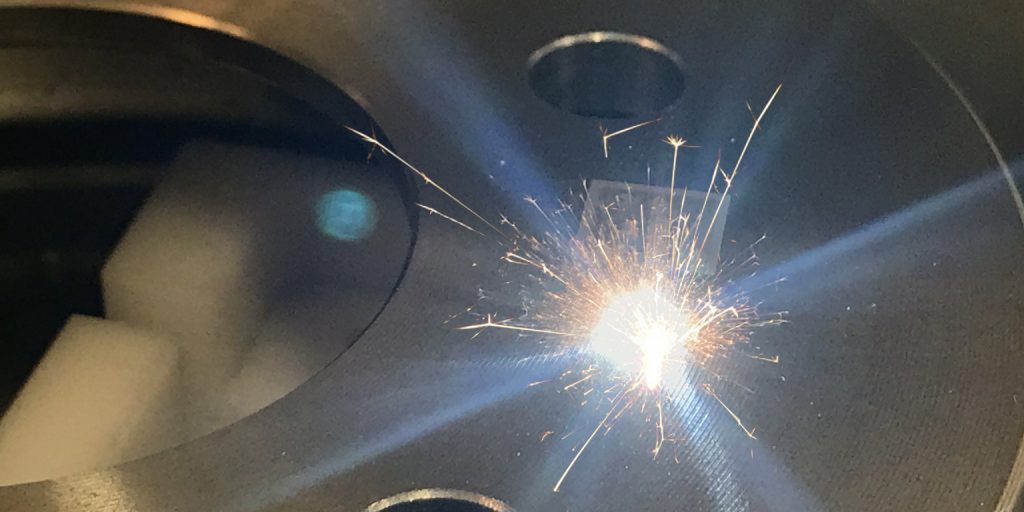

After PCB laser marking and depaneling

PCB surface cleaning before solder paste printing

70% of the errors in SMT processes occur before the soldering process. The quality of the soldering paste print is directly related to the level of contamination on the printed circuit. SMT-II removes this variable from the process by cleaning the pad surface immediately before applying the soldering paste.

Teknek SMT-II is offered with Nanoclean technology, a silicone-free cleaning system. This system allows you to clean the contaminant particles on the surface without touching the line without allowing the accumulation of static electricity charge.

PCB surface cleaning after laser marking

SMT-II Technical Specifications

| PROCESS | |||

|---|---|---|---|

| Double Sided Cleaning | Min – Max Length Min – Max Width Min – Max Depth | 98mm – Not applicable 40mm – 400mm 0.6mm – 3.2mm | 98mm – N/A 40mm – 600mm 0.6mm – 3.2mm |

| Bypass | Min – Max Length Min – Max Width Min – Max Depth | 120mm – Not applicable 40mm – 400mm 0.6mm – 3.2mm | 120mm – N/A 40mm – 600mm 0.6mm – 3.2mm |

| Single Sided Cleaning | Min – Max Length Min – Max Width Min – Max Depth | 50mm – Not applicable 40mm – 400mm 0.6mm – 3.2mm | 50mm – N/A 40mm – 600mm 0.6mm – 3.2mm |

| Bypass | Min – Max Length Min – Max Width Min – Max Depth | 50mm – Not applicable 40mm – 400mm 0.6mm – 3.2mm | 50mm – N/A 40mm – 600mm 0.6mm – 3.2mm |

| Features | |

|---|---|

| Two Different Width Models | 40 – 400mm / 40 – 600mm |

| Working Modes | Double Sided – Bypass Single Sided – Bypass |

| Roll Types | Nanocleen™ 20.20 |

| Glue | Low Static Adhesive Roll |

| Processing Speed | 1-40 m/mm |

| Transition Line Height | 900±50mm |

| Power supply | International |

| Required Pneumatic Pressure | Oil-free 5 -7 Bar air pressure |

| ESD Compatibility | |

|---|---|

| Device | ANSI / ESDs 20.20 – 2014IEC 61340-5-1:2016 |

| NANOCLEEN™ 20.20 | ANSI/ESDs 6.1 – 2014IEC 61340-5-1:2016 |