ProDisp DD2510-MX Meter Mix Dosing Glue Potting Machine

Dosing Resin Glue Potting Machine

The ProDisp DD2510-MX is a powerful dispenser designed for distributing all types of filling materials, including PU, silicone, and epoxy. It mixes the components, allowing you to easily fill and insulate capacitors, power supplies, transformers, ignition coils, power electronics circuits, ballasts, and other products that require sealing and protection from environmental conditions.

Long Life and Casting Quality with Heated Vacuum Technology

In resin dispensing, the mixed liquid can be abrasive, causing friction in the pump due to its abrasive nature. Air bubbles in the resin structure are undesirable, leading to rapid wear of the pump and making its use more difficult.

We have addressed this issue with the ProDisp DD2510-MX Meter Mix Filling Machine by using vacuum technology to remove air bubbles. We have also incorporated a heated system to make mixing easy and comfortable, extending the pump’s lifespan. Additionally, we designed the machine with a self-cleaning feature to facilitate the easy disposal of hazardous waste.

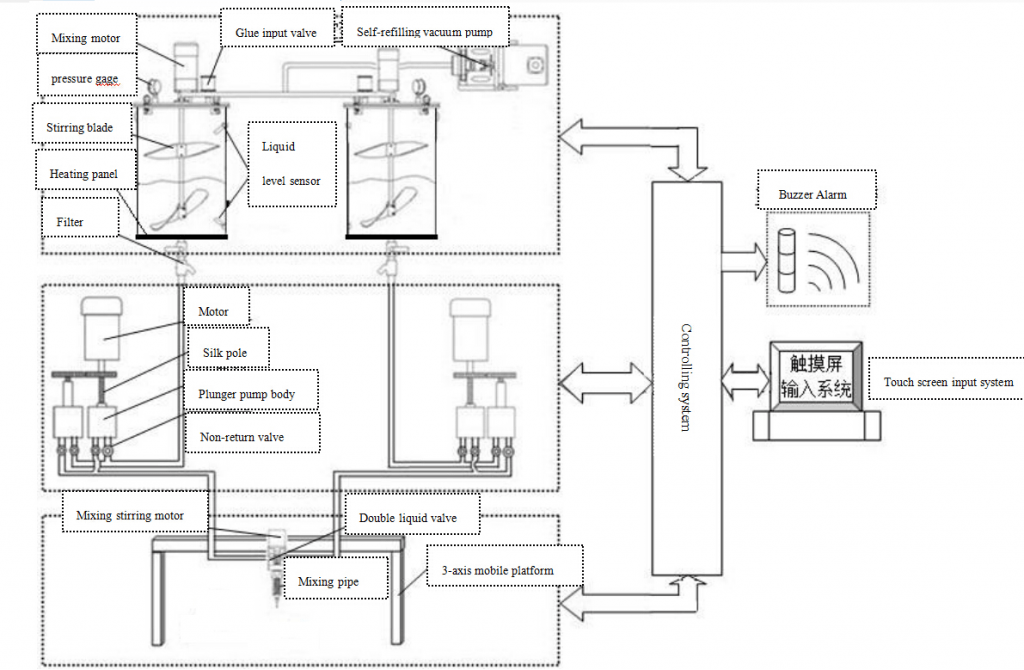

Liquids A and B are stored separately in two tanks. Inside the machine, there are two sets of measurement pumps that discharge the liquids from tanks A and B individually. Liquids A and B mix in the mixer tube and are dispensed according to programmable data.

Features

**Features:**

1. **Automatic Measurement and Mixing:** Touchscreen PLC control system with an English operating interface, making parameter adjustments easy.

2. **Large LCD Screen:** Displays various process data.

3. **Adjustable Dispensing Speed and Timing:** Allows for precise control.

4. **Mixing Ratio:** Adjustable from 1:1 to 1:10, with the dispensing volume customizable to actual needs. Dynamic mixing ensures a fully homogeneous consistency of the two-component adhesive.

5. **Simultaneous Measurement and Mixing:** Ensures efficiency in the dispensing process.

6. **Two Tanks:** Keeps A and B adhesives separate.

7. **Liquid Level Sensor:** Includes an alarm function.

8. **Optional Tank Mixing and Vacuum Foam Removal Functions:** Enhances performance.

9. **Automatic Cleaning:** Can be manual or automatic. Manual mode requires removing the mixing tube, soaking it in cleaning agent for 10 minutes, and then cleaning with compressed air. Automatic mode completes cleaning with a touch of a button on the touchscreen within 1 minute.

10. **Heating Function:** Optional heating for adhesive tanks, measurement pumps, and adhesive tubes.

11. **Vacuum Control:** Prevents dripping of fine liquids.

12. **Unique Control System:** Insensitive to air pressure factors, ensuring optimal dispensing performance.

13. **Programmable XYZ Axis:** Allows adhesive dispensing along desired patterns.

14. **Tally Function:** Includes non-standard mode, primer mode, level warning, filter mode, liquid viewing device, anti-backflow device, and other functional devices.

Advantages of Automatic Glue Potting Machine:

1. Fully automatic operation, accurate ratio and even mixing.

2. No adhesive waste or material waste during mixing. Precise dosing and distribution.

3. Consistent and high-quality adhesive amount. The machine’s edges remain clean of adhesive.

4. The machine saves a lot of time, is effective, and provides lower costs.

5. No need for adhesive dispensing personnel; only one operator is required to complete serial production.

Glue Potting machine working principle

1. Ratio between base agent and hardener: 1:1 or 10:1.

2. Filling Materials: Abrasive base agents, including additives and fillers such as aluminum oxide or silica powder to increase hardness or heat transfer.

3. The mixed liquid is abrasive, causing significant friction in the pump.

4. Vacuum is needed to remove air bubbles inside.

5. Even mixing of the two components is not easy.

6. Vacuum: To remove air bubbles from the adhesive.

7. Self-cleaning.

8. Heating: Preheat the resin before use.

9. Dynamic Mixing Method for even mixing.

10. Daheng Patent Measurement Pump: Non-abrasive, long-lasting; high precision; multiple nozzles to increase capacity.

11. High Precision Valve.

12. Quality and strict position control system.

13. Multi-head nozzle available.

Technical Data

Suitable Adhesives:

AB crystal adhesive: For hermetic applications and application pots.

Room pot adhesive for insulation (with fillers): Two-component silicone, polyurethane, AB adhesive, epoxy parts.

Applications

Application of Crystal Adhesive:

Surface bonding: Flexible strips, photo albums, mosaic tiles, stickers, badges, refrigerator decals, bra hooks, insoles, snowboard decals, tile decals, and other crafts.

Resin for LED lamps: Isolation of small modules, vases, digital tubes, and other products requiring isolation.

Filling Adhesive Potting Applications:

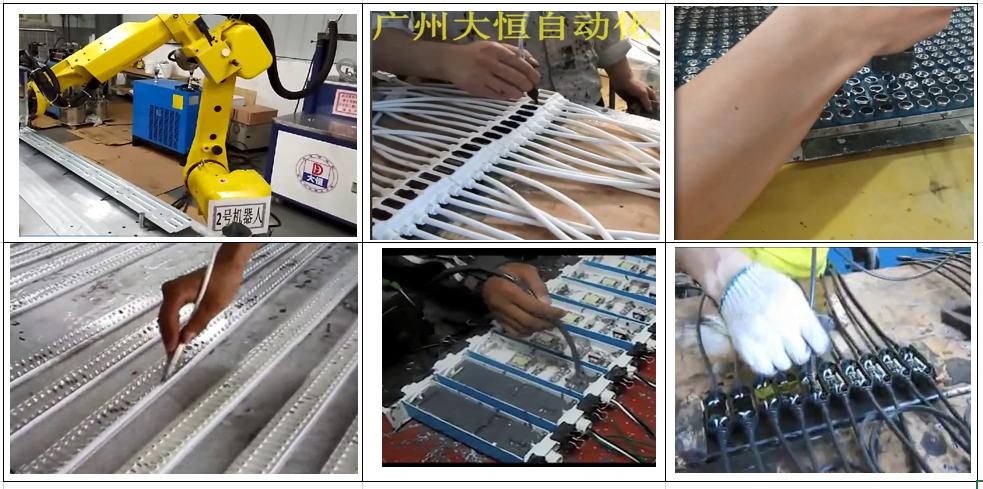

- LED Products: LED displays, LED screens, outdoor wall washers, outdoor hard lights, underground lamps, underwater lights.

- Electronic Components: Microelectronics, coils, transformers, ballasts, electronic coils, relays, speakers, heating elements, coils, etc.

- Automotive: Headlights, generators, clutches, air filters, oil filters, car control boards, horns, flashers, electric vehicle accessories.

- Communications Parts: Communication boxes.

- Water Treatment: Water filters, water meters, etc.

Other products also require potting processes.

Technical Table

| Feature | Specification |

|---|---|

| Adjustable Ratio | 1:1 — 10:1 |

| Output Speed | 0.5g/sec — 15g/sec |

| Mixing Accuracy | +/- 2% |

| Program Memory | 20 programs |

| Viscosity | 300 cps ~ 50,000 cps |

| Operation Mode | Manual / Automatic / Third-party signal |

| Ratio Control | PLC / Dual-cylinder diving pump |

| Flow Control | Digital input |

| Program Mode | Technology program |

| Control System | Touchscreen and trigger |

| Mixing Mode | Dynamic mixing (with self-cleaning function) |

| Adhesive Tank | Stainless tank A & B |

| Voltage | 220V / 50Hz / 3500W |

| Input Air Pressure | 0.4 MPa — 0.7 MPa |